4-6 s / bag Packing Dry Mix Mortar Mixing Plant Wall Putty Tile Adhesive Glue Grout Making Machine

1. Description of Dry Mix Mortar Tile Adhesive Mixing Plant.

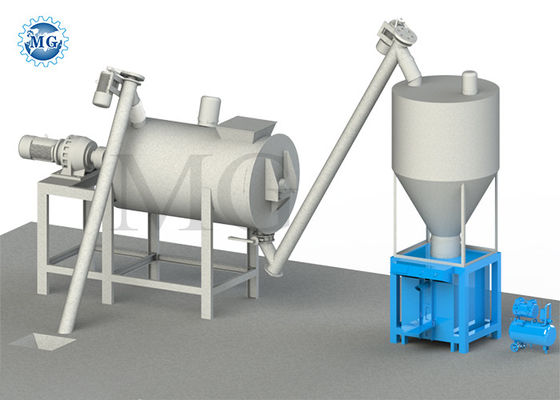

MG series Dry Mix Mortar Mixing Plant is designed according to the traditional single mixer machine, and adding material transportation system, finished product storage silo and automatic packing machine, and forms one whole simple dry mortar production line, improves the working efficiency a lot, it can finish the work from feeding, mixing, conveying to packing automatically.

We can design the production line according to customers' different kinds of requirement. We can add the loading screw conveyor machine for our customer if they need, we can also equip different kinds of packing machine for our customer, including the valve type packing machine and open type packing machine, we can also add the automatic weighing scale to the production line according to our customer need.

The whole production line only require 2-3 workers to operate it, which can save a lot labor. Its capacity include 3-4 t/h, 4-6 t/h, 7-8 t/h. It can realize fast money feedback with low investment, it need very few fund, labor and land, it is very easy to install and operate, it's the best choice for the starter in dry mortar industry.

2. Product Configuration of Dry Mix Mortar Tile Adhesive Mixing Plant.

| Model |

Capacity |

Occupied area |

Equipment height |

Manpower |

Batching and packaging |

| Simple type |

1-8t/h |

20㎡ |

3-4m |

2-3 Person |

Manual batching

Automatic packaging |

| Semi-automatic type |

6-8t/h |

50-60㎡ |

6-8m |

3-4 Person |

Manual batching

Automatic packaging |

| Full automatic type |

8-30t/h |

60-100㎡ |

8-13m |

3-4 Person |

Automatic batching

Automatic packaging

|

1. Ribbon Mixer Machine.

The screw ribbon mixer is the most high economy and cost-effective dry mortar mixer,the outer and inner screw ribbon blade driven by high speed rotating shaft, mixing the material in maximum, inner screw ribbon blade forced the material to sides, outer screw ribbon blade forced sides material to inward, mix the materials back and forth. so to achieve uniform mixing effect in relatively short time. This is its working principle,the mixing time is about 10-15min/batch.

The screw conveyor is Φ165X3500mm, the mixer mortar is transferred from mixer to finish product hopper.

3. Finished Product Storage Silo.

The finished product hopper is about 1.5m³, to store the finished material and prepare for the packing machine, which improves the efficiency a lot.

4. Automatic Packing Machine.

Automatic dry mortar packing machine,valve type, 15-50kg/bag adjustable, 4kw, the packing speed is about 5-6s/bag. High packing speed, high weighing accuracy, high degree of automation, simple operation,and easy maintance.

0.25m³, 2.2kw, providing air source for automatic packing machine and finished product hopper,achieving quick packing and broken arch of finish product hopper.

3. Working Principle of Dry Mix Mortar Tile Adhesive Mixing Plant.

MGDM-3.0 dry mix mortar mixing plant mainly has the first feeding screw conveyor, the multi-spiral ribbon mixer, the second discharge screw conveyor, the finished product hopper, the automatic valve bag packing machine, air compressor and a control panel. This is simple and practical, occupies small area, low investment costs, low maintenance costs, and is ideal for small dry powder product processing plants.

When the dry mix mortar tile adhesive mixing plant works, firstly, the raw material is put into the feeding pot of screw conveyor, then transported into the mixer by screw conveyor,secondly, several kinds of raw material will be mixed by the multi ribbon screw mixer, thirdly,the mixed material will be transported into the end product silo by second screw conveyor, fourthly, the finished product will be packed into bags by packing machine.

4. Raw Materials of Dry Mix Mortar Tile Adhesive Mixing Plant.

5. Application of Dry Mix Mortar Tile Adhesive Mixing Plant.

6. FAQ

1. What is the capacity of your automatic dry mortar mixing plant?

A: We have dry mortar mixing plant capacity ranges 3-50T/H as your requirement, And also we can customize the production line for you.

2. Can you provide formula of different kind of dry mortar?

A: Yes,we can, we have been professional dry mortar production equipment supplier for more than 20 years, we have many customers all over the world, and we are very experienced in dry mortar production field, we are an executive member of Chinese private Technology Promotion Committee and building materials Experts Association, we can provide all kinds of best formula for our customers.

3. What is the guarantee of the equipment?

A: 12 months, with in this period we provide you technical services for free.

4. What is your business model? Trading company or factory?

A: We are a factory with our own mechanical design engineers and project design engineers, all our machinery are manufactured by ourselves.

We can provide customized solution design according to customer needs, and full-process services such as early project communication, scheme design, equipment selection, equipment production, site planning, equipment layout, transportation and delivery, installation and commissioning.

5. Do you provide after-sale service?

A: Yes. The warranty period of our machines is 12 months, and we have a professional after-sale service team to promptly and thoroughly solve your problems.

If you are interested to our dry mortar production line, please feel free to send us inquiry or leave your contact number for us.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!